Still Using Spreadsheets ?

Upgrade to Wrysto

The Best ERP With CMMS

for Power Plants and Industrial Operations

Still using spreadsheets for maintenance? Upgrade to Wrysto the best ERP with CMMS. Digitize work orders, automate preventive maintenance, and get real-time KPIs that reduce downtime and lower costs.

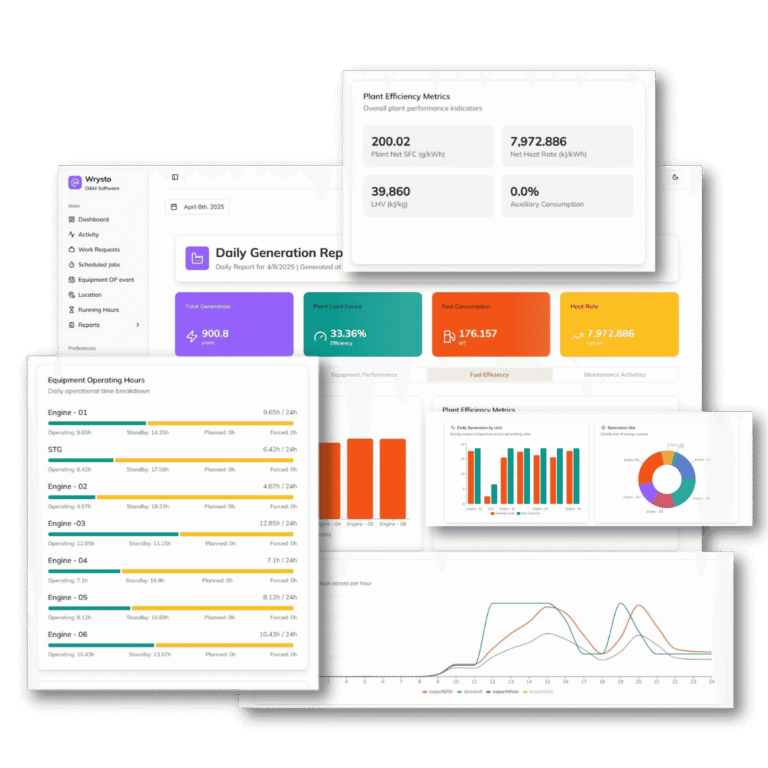

Performance App

Why Wrysto is the Best ERP With CMMS

Wrysto combines ERP-grade asset control with a powerful CMMS tailored for engineers, and O&M managers, Owners And stakeholders . Eliminate paperwork, enforce accountability, and centralize maintenance data across departments and sites.

- Role-Based Work Order Management

- Preventive Maintenance Scheduling

- Performance & Field Reporting

- HR solution

- Inventory & Spare Parts Managment

- Custom Dashboards , live KPIs and asset

Features

One Dashboard. Every Task.

Total Clarity — That’s Wrysto

Wrysto doesn’t just track your work orders — it empowers your team with real-time visibility into maintenance progress, equipment condition, and operational bottlenecks.

Paperless Work Order Management

Create, assign, and track preventive and corrective maintenance tasks. Automatically log work history for future audits and compliance

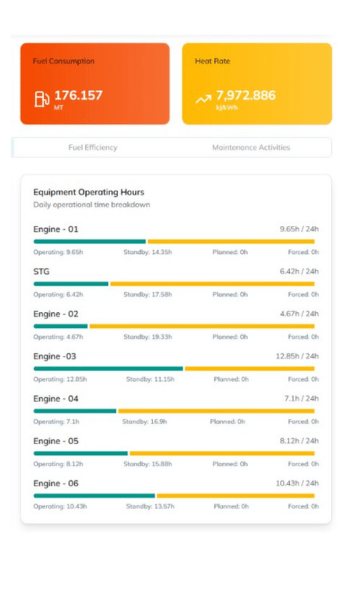

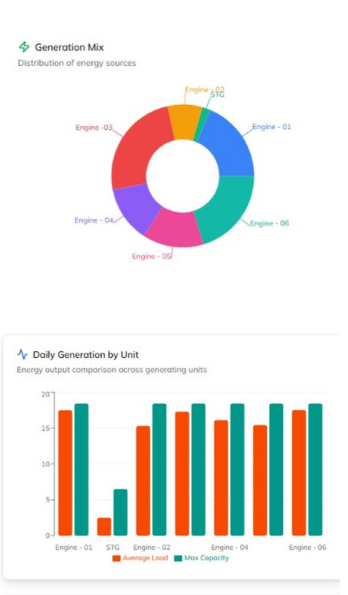

Advanced Reporting & Insights

Access daily generation reports, hourly readings, KPI dashboards, and maintenance logs to support real-time decision-making.

Complete Workflow Tracking

Monitor every stage of a work request — from PLACED to FINISHED — with full audit trails and live status updates.

Scheduled Maintenance Management

Automatically schedule PM based on running hours, time, or condition.

Multi-user Role-based Access

Operators, Engineers, In-charges, Managers — each gets tailored access. Ensure accountability with activity logs and audit trails.

Secure Cloud Access

Accessible from laptop or mobile — no software installation required. Data stored securely with regular backups and SSL encryption.

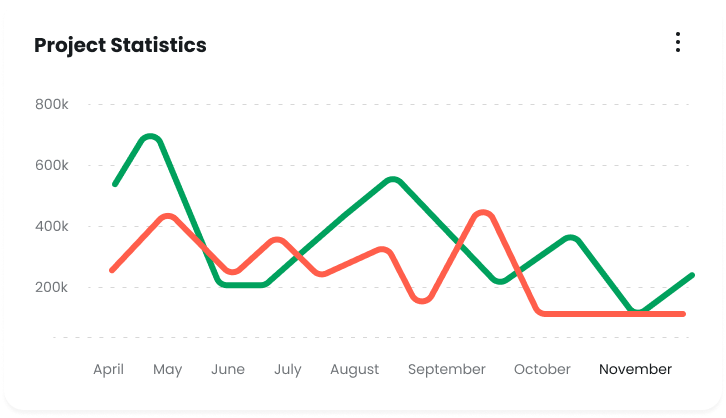

kpi

Equipment KPI Tracking – Smarter, Not Harder

Wrysto gives you a real-time view of how your critical assets are performing, enabling proactive decision-making

- Track MTBF & MTTR

- Monitor downtime per asset

- Visualize asset reliability and availability trends

- Service history for each equipment

No more guesswork. Know exactly which equipment is costing you time, money, and performance.

kpi

Field Engineer KPI – Performance You Can Measure

Wrysto turns daily technician activity into measurable insights:

- Track work order completion time and accuracy

- Monitor first-time fix rate and task delays

- Evaluate response time from request to execution

- Assign tasks based on skillset and past performance

💡 With Wrysto, maintenance managers and plant leadership can identify:

- Who’s performing well — and why

- Where training or resource gaps exist

- How to reward, promote, or restructure teams

FAQ

Frequently Ask Questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Wrysto replaces manual logs with automated PM scheduling, centralized work orders, and KPI dashboards that reduce reactive work and extend asset life.

Yes. Role-based access and custom dashboards ensure operators, maintenance crews, and managers see tailored views and consolidated reports.

Yes. Digital logbooks, time-stamped audit trails, and exportable records simplify audits and regulatory reporting.

Absolutely. Wrysto has built-in KPI tracking for both equipment (e.g., breakdown frequency, MTBF, MTTR) and personnel (e.g., task completion time, backlog clearance rate). These metrics help managers identify underperforming assets and training needs for technicians.